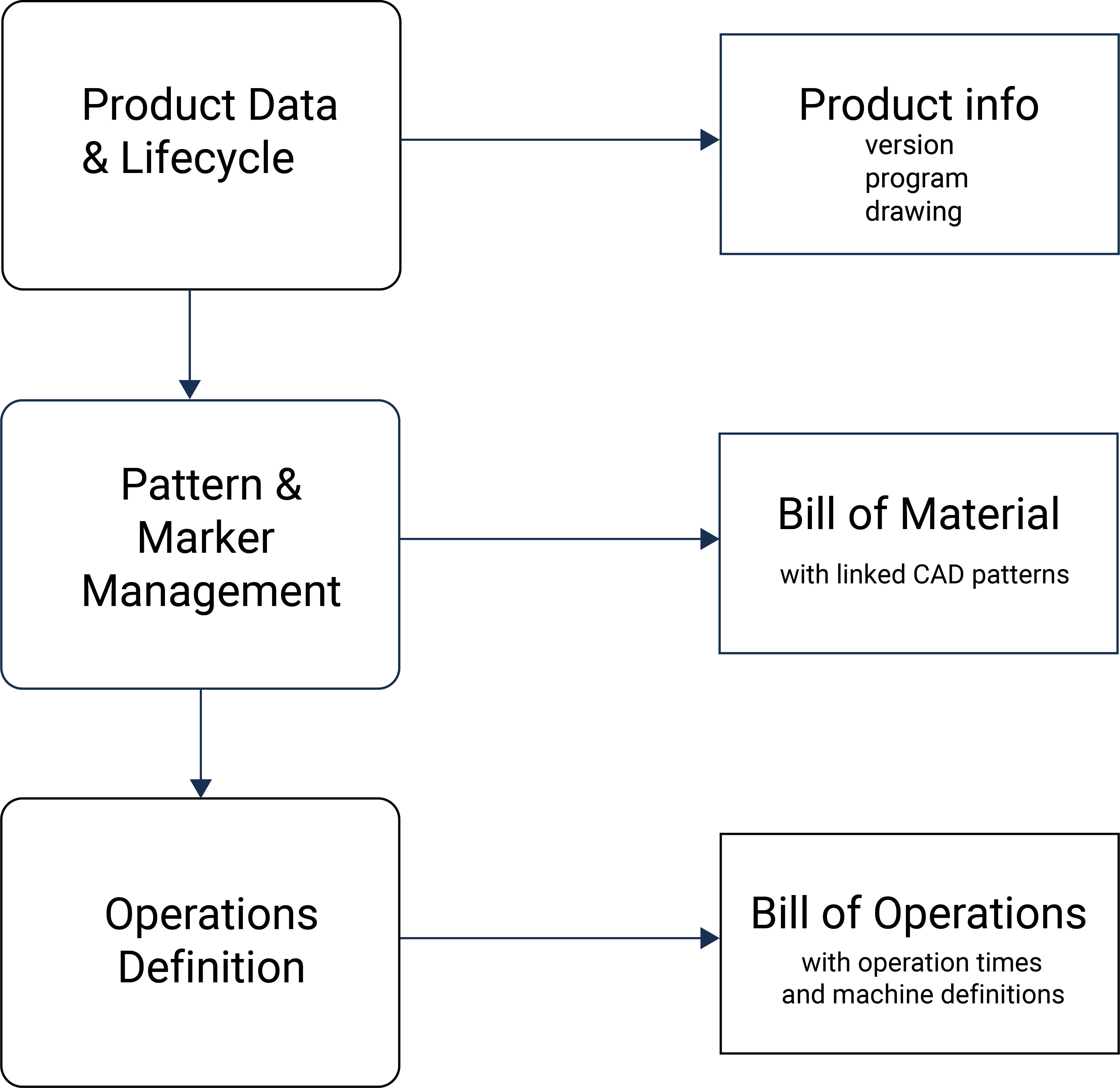

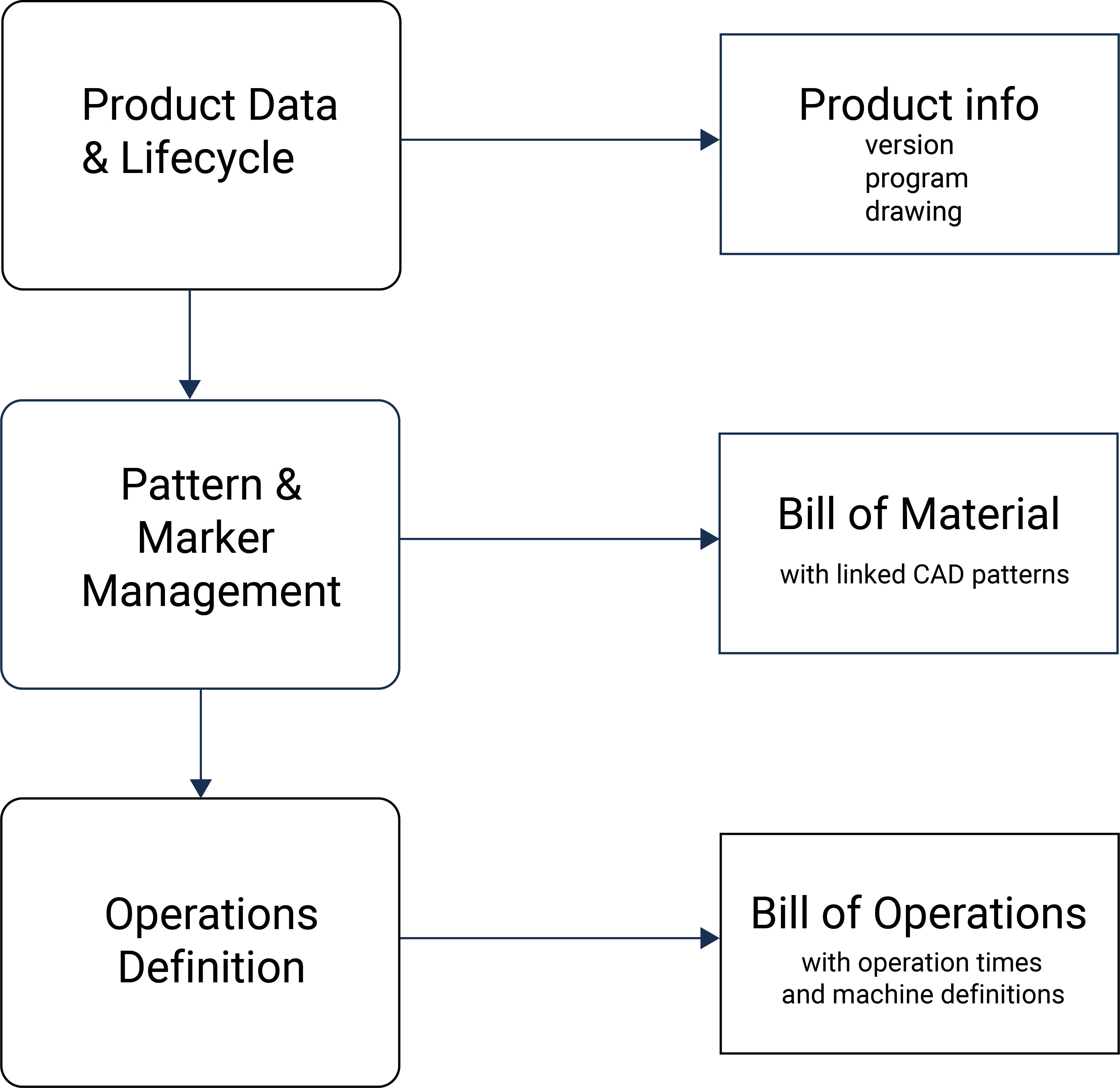

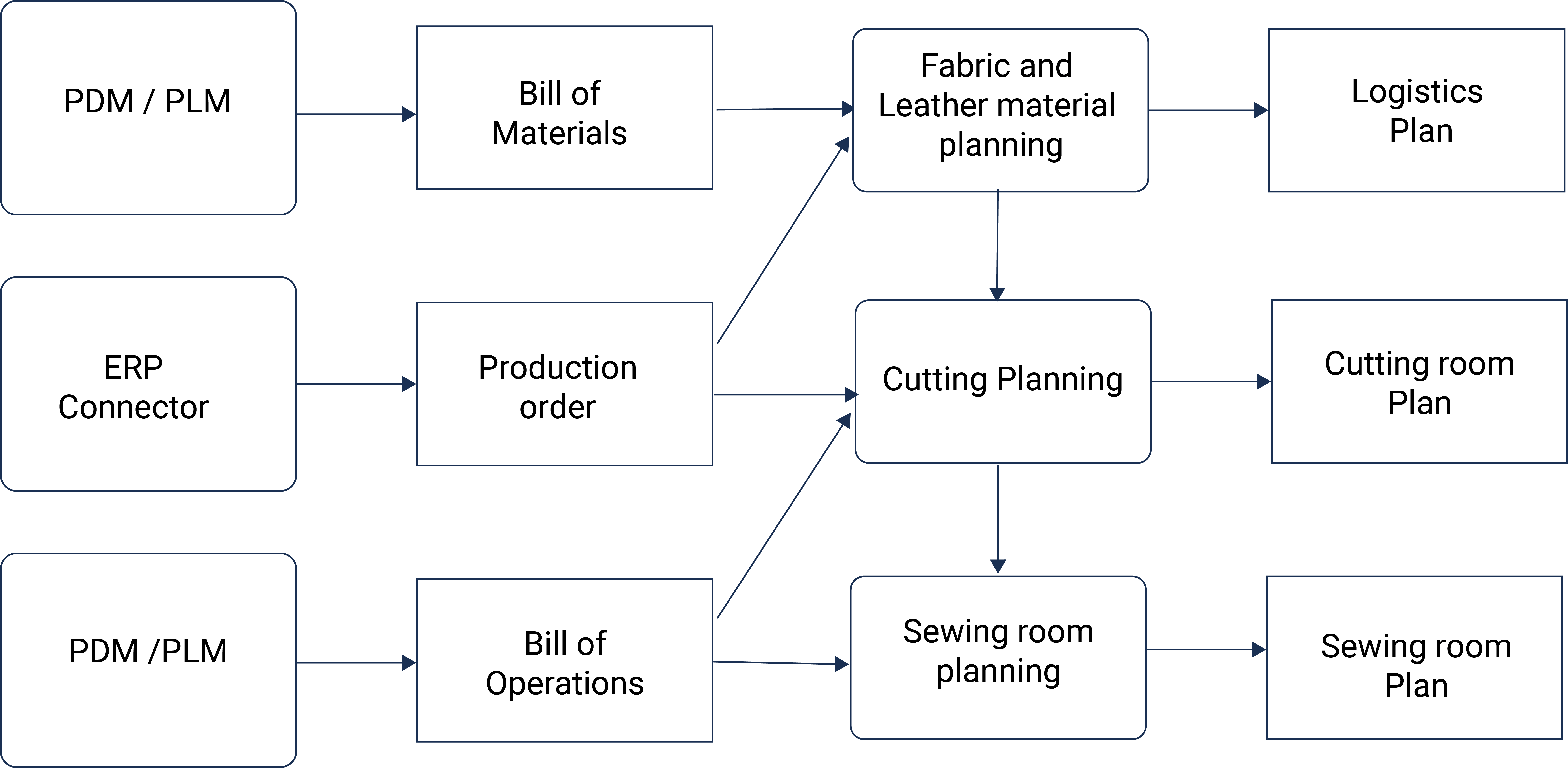

Development (PDM/PLM)

Product Data & Lifecycle

- Fully configurable and integated significantly reduces the development process.

- Version control, change and release management.

- Bill of Materials with CAD-patterns integrated.

- Development tracking.

- Program managment.

Pattern and Marker management

- Pattern import from standard CAD systems Lectra, Gerber, Optitex and Autocad.

- Automatic pattern numbering and version management.

- Linking patterns with materials and BOM.

- Automatic marker creation and nesting for minimal fabric consumption.

- Marker database and cutting file generation.

Operations defintion

- Visually define (sewing) operations on a style based on patterns.

- Automatically calculate sewing time and yarn consumption.

- Machine and operations database.

- Exchange Bill of Operations with planning production system.

- Calculate operations times cost.

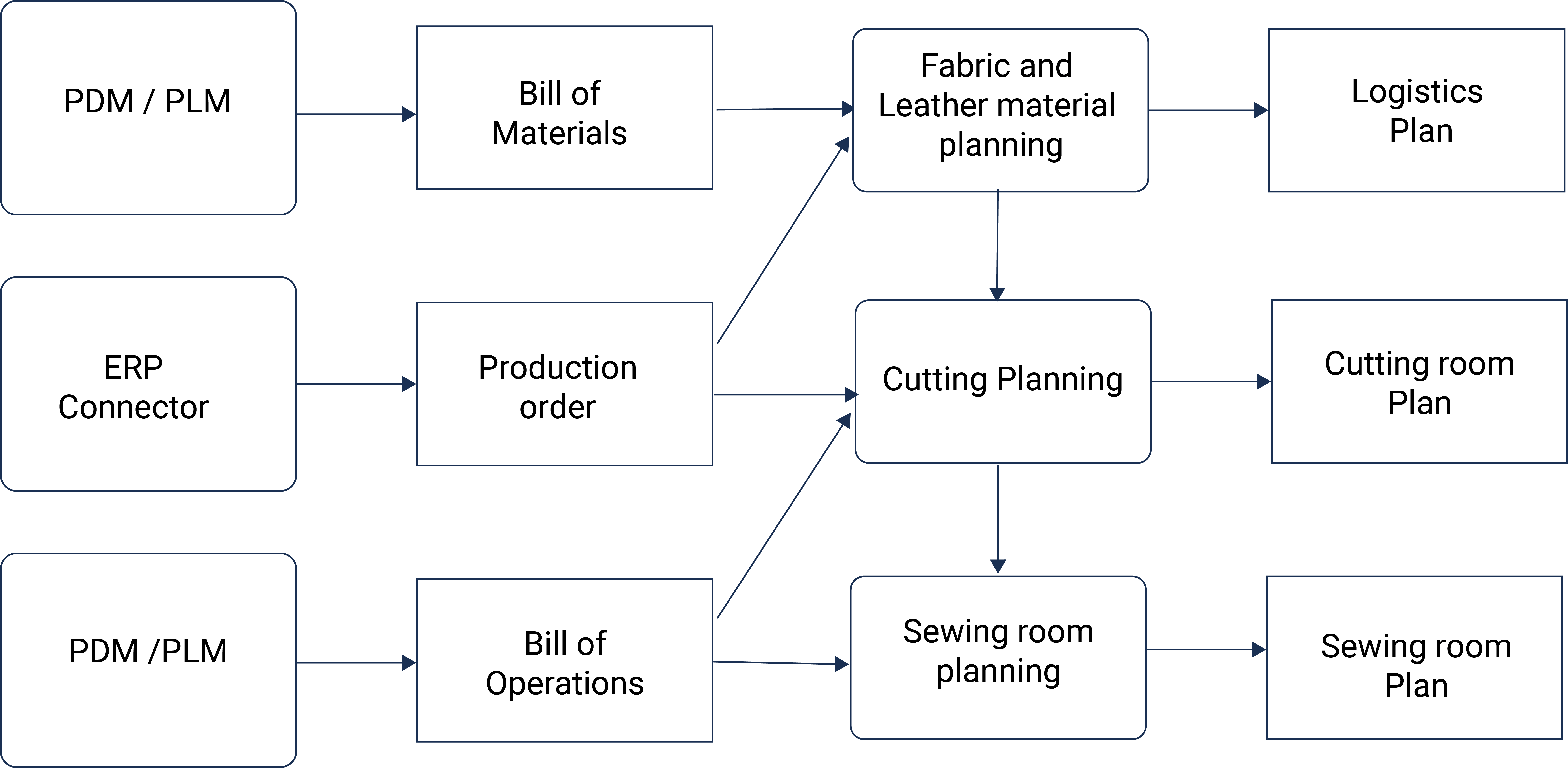

Planning

Fabric and leather material

- Fabric roll management with production batch checking.

- Leather hide import with quality zones from leather scanning systems.

- Automatic leather hide qualification and supplier rating.

- Automatic leather nesting for minimal waste.

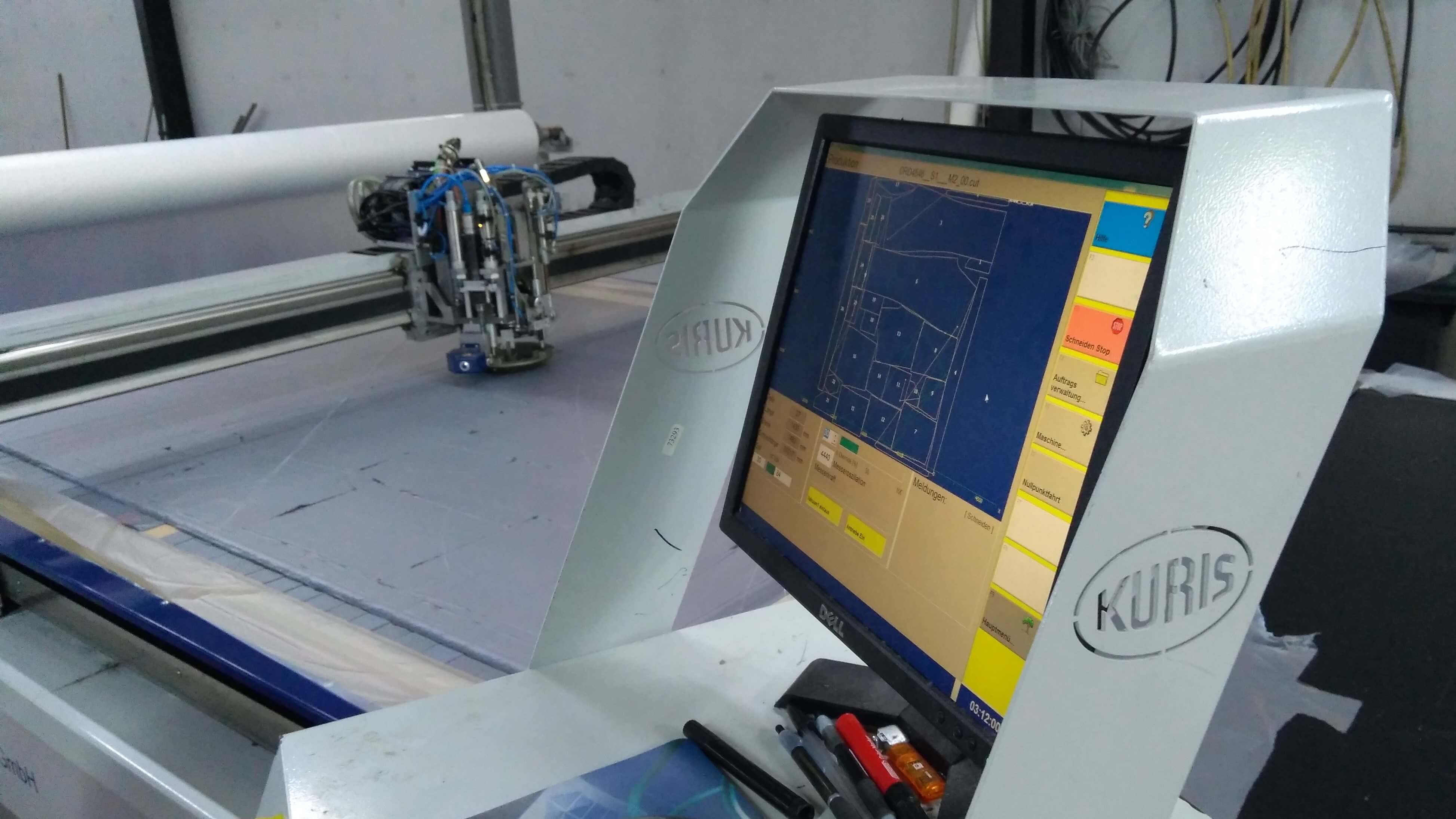

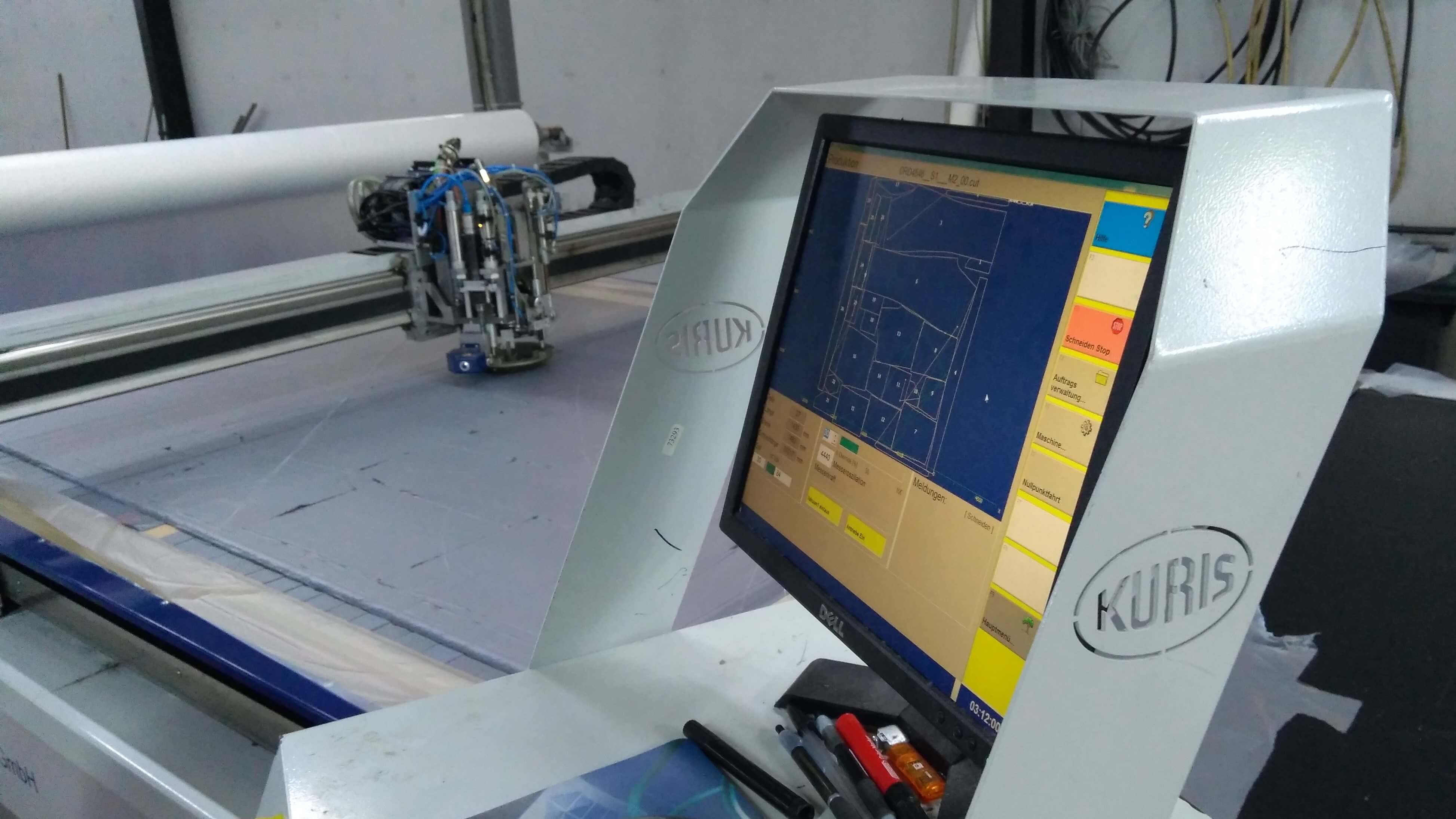

Cutting room

- Preparation and planning of cutting operations.

- Controlling jobs for automatic cutting machines.

- Calculate expected cutting time and capacity planning.

- Integration with for marker and leather management.

- Fabric and Leather cutting files generation for automatic cutting machines.

Sewing room

- Production floor machine and material flow definition.

- Operator database with efficiency and learning curves.

- Operator attendance registration.

- Machine and operator resource calculation.

- Production line balancing based on production orders and product (sewing) operations.

Quality management and Production Part Approval (PPAP)

- Full Production Part Approval.

- Process (PPAP) management.

- Support of different international standards.

- Storing test result and quality declarations.

- Automatic reminders and support for the requalification process.

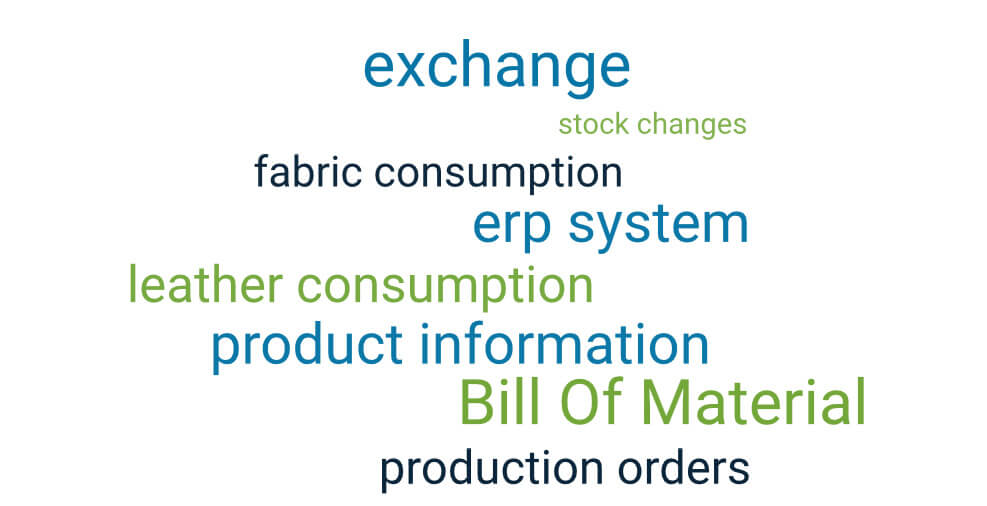

ERP connector

- Exchange information with ERP-systems.

- Style and product information.

- Bill of Materials with updating fabric and leather consumption.

- Integration with for marker and leather management.

- Production orders.

- Stock changes.

Production

Cutting Management and Visualisation

- Visualisation of cut pieces, coloring by type or product for ppeeding up cutted pieces sorting and take-off.

- Cutfile and marker management.

- Direct interface with automatic cutters.

- Fabric and leather cutting support, ERP stockupdate.

- Single ply and multiple ply cutting support.

Quality control and spare pieces management

- Registering defective pieces after cutting or sewing processes.

- Possibility to measure dimensions based on pattern on screen.

- Stock management of spare pieces.

- Automatically creating cutting orders for compensation of defective pieces.

Sewing Management

- Production line balancing based on sewing plan and production order.

- Scanning finished products and label printing.

- Monitoring production order progress and bottle necks.

- Registering operator replacements and machine defects and downtime.

- Efficiency calculation and ERP stock update.

- Visualisation of production progress.