Design and Prototype Management

Design

- All design information for new styles and products in a central place.

- Communicate with your design team.

- Exchange sketches, ideas, pictures etc.

- Overview of the new collection.

- Follow up the design workflow.

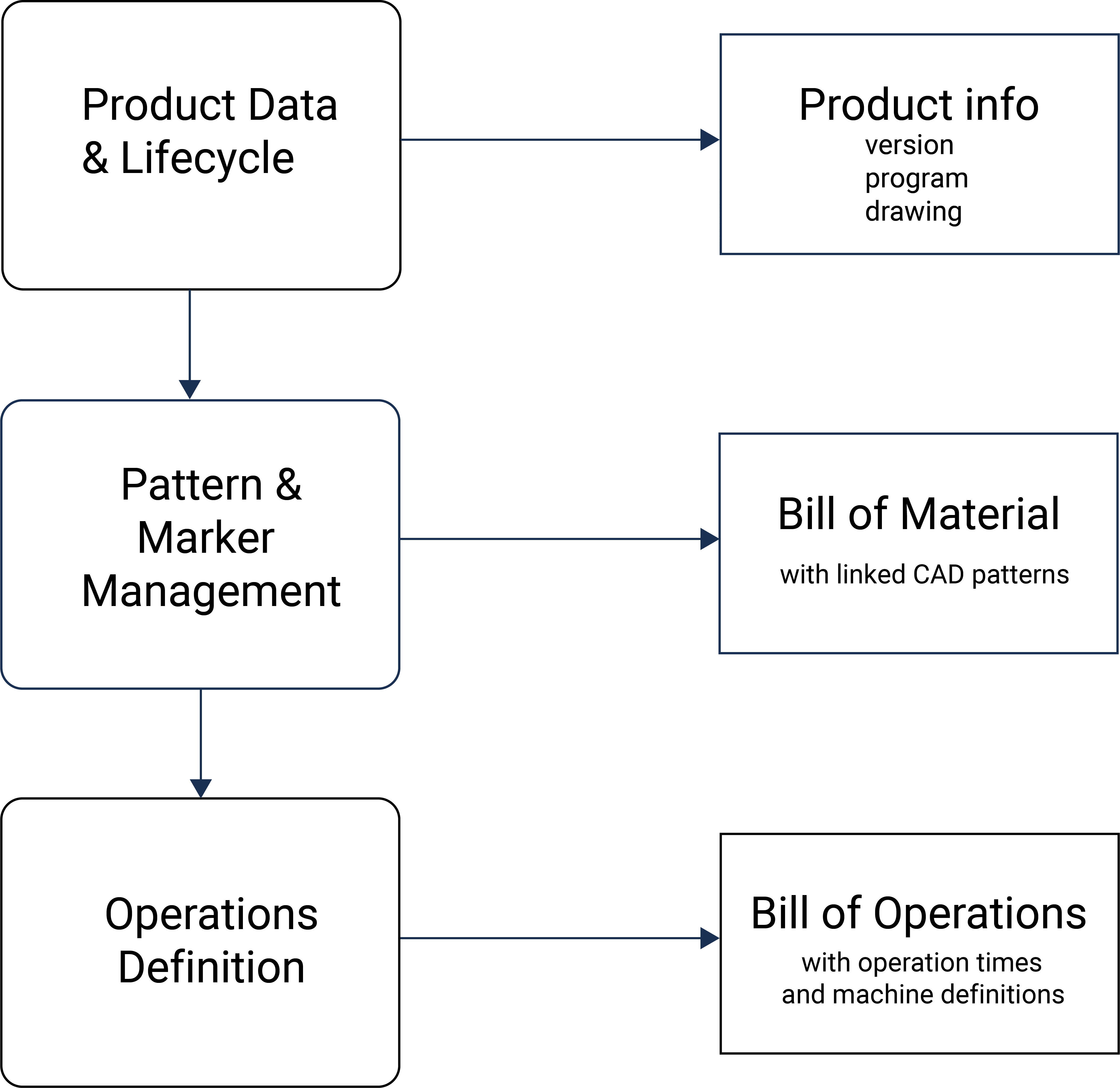

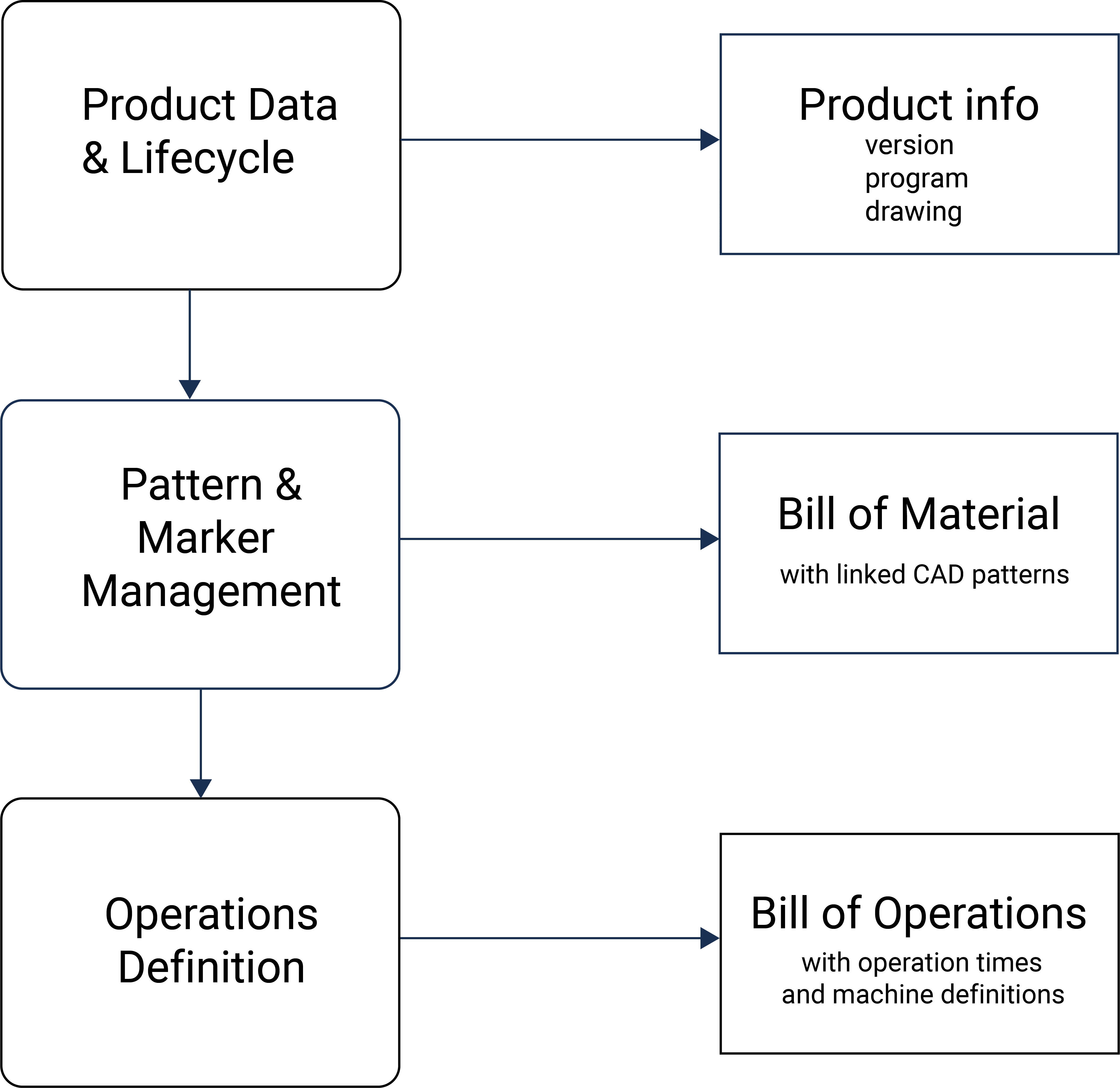

Product Data and Lifecycle Management

- Fully configurable significantly reduces the collection development.

- Full information for production and sales channels.

- Bill of Materials, color and size specifications.

- Pattern and fitting information.

- Follow up design and production workflow.

Prototype

Pattern and Marker management

- Pattern import from standard CAD systems Lectra, Gerber, Optitex and Autocad.

- Automatic pattern numbering and version management.

- Linking patterns with materials and BOM.

- Automatic marker creation and nesting for minimal fabric consumption.

- Marker database and cutting file generation.

Operations definition

- Visually define the operations on a style based on patterns.

- Automatically calculate sewing time and yarn consumption.

- Machine and operations database.

- Exchange operator instructions with production system.

- Calculate operations cost.

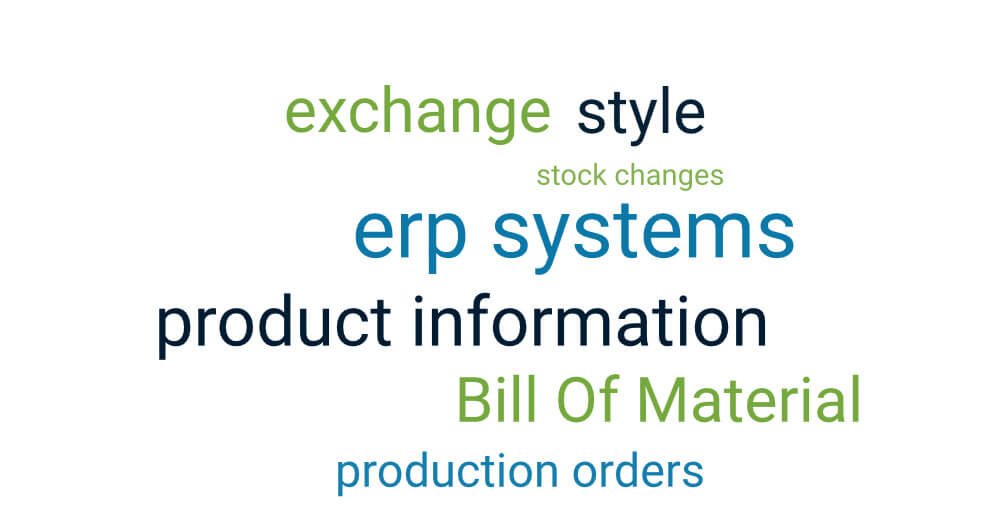

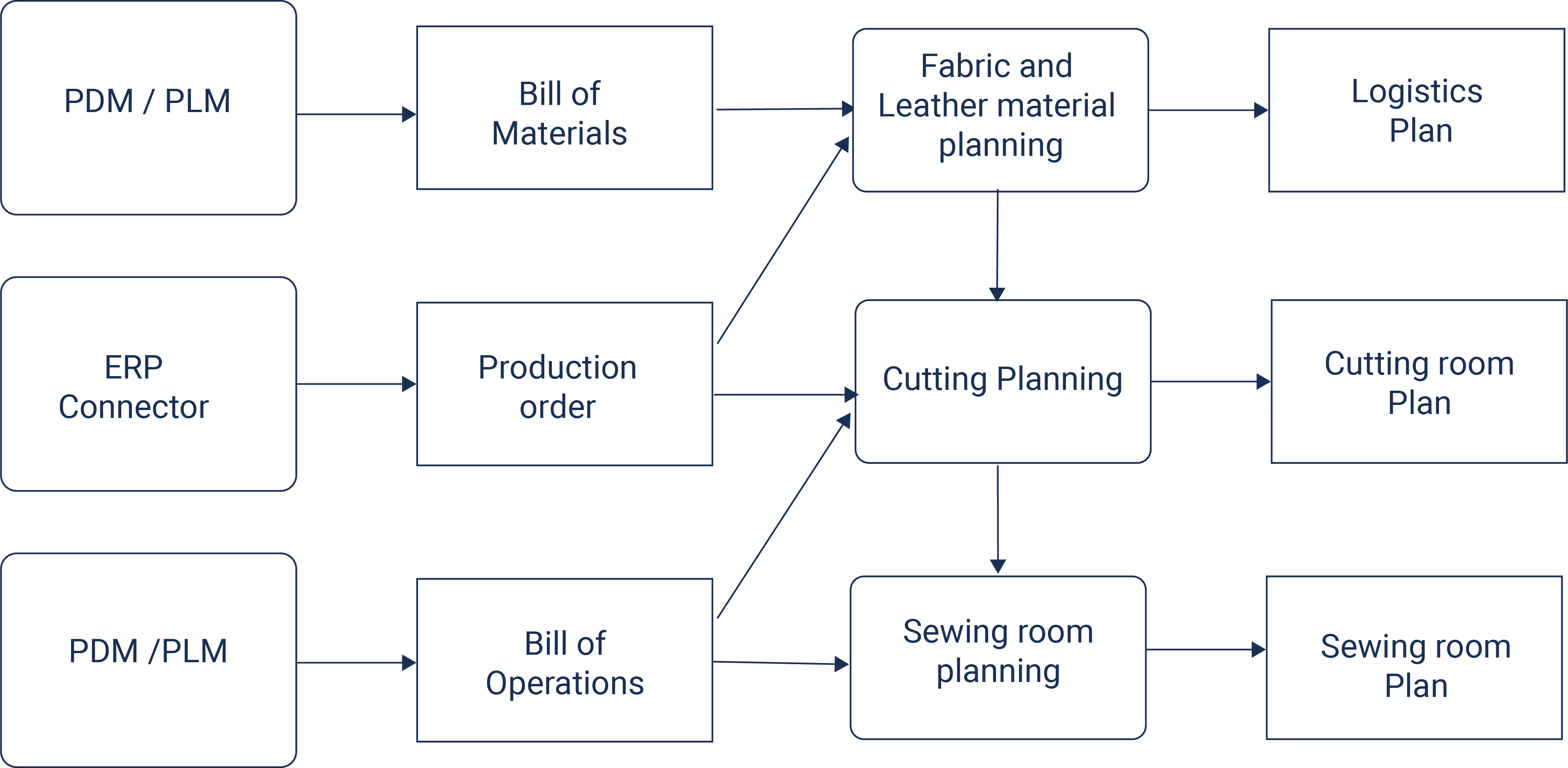

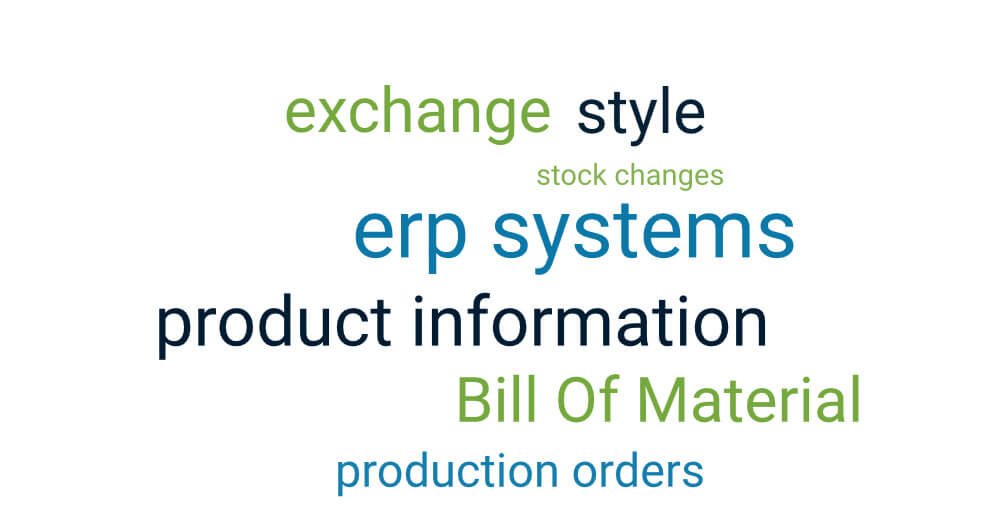

ERP connector

- Exchange information with ERP-systems.

- Style and product information.

- Bill of materials.

- Production orders.

- Stock changes.

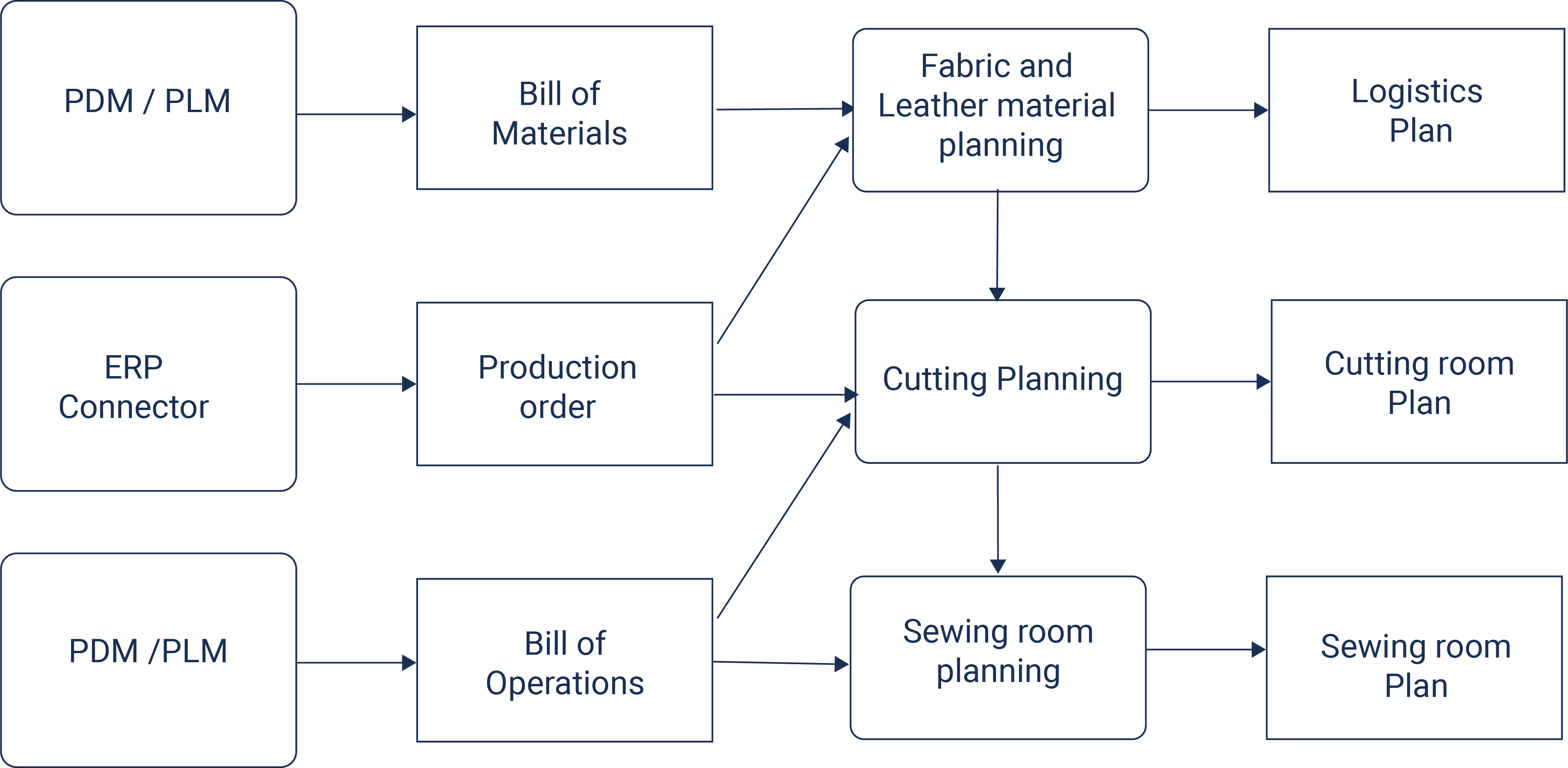

Planning and Production

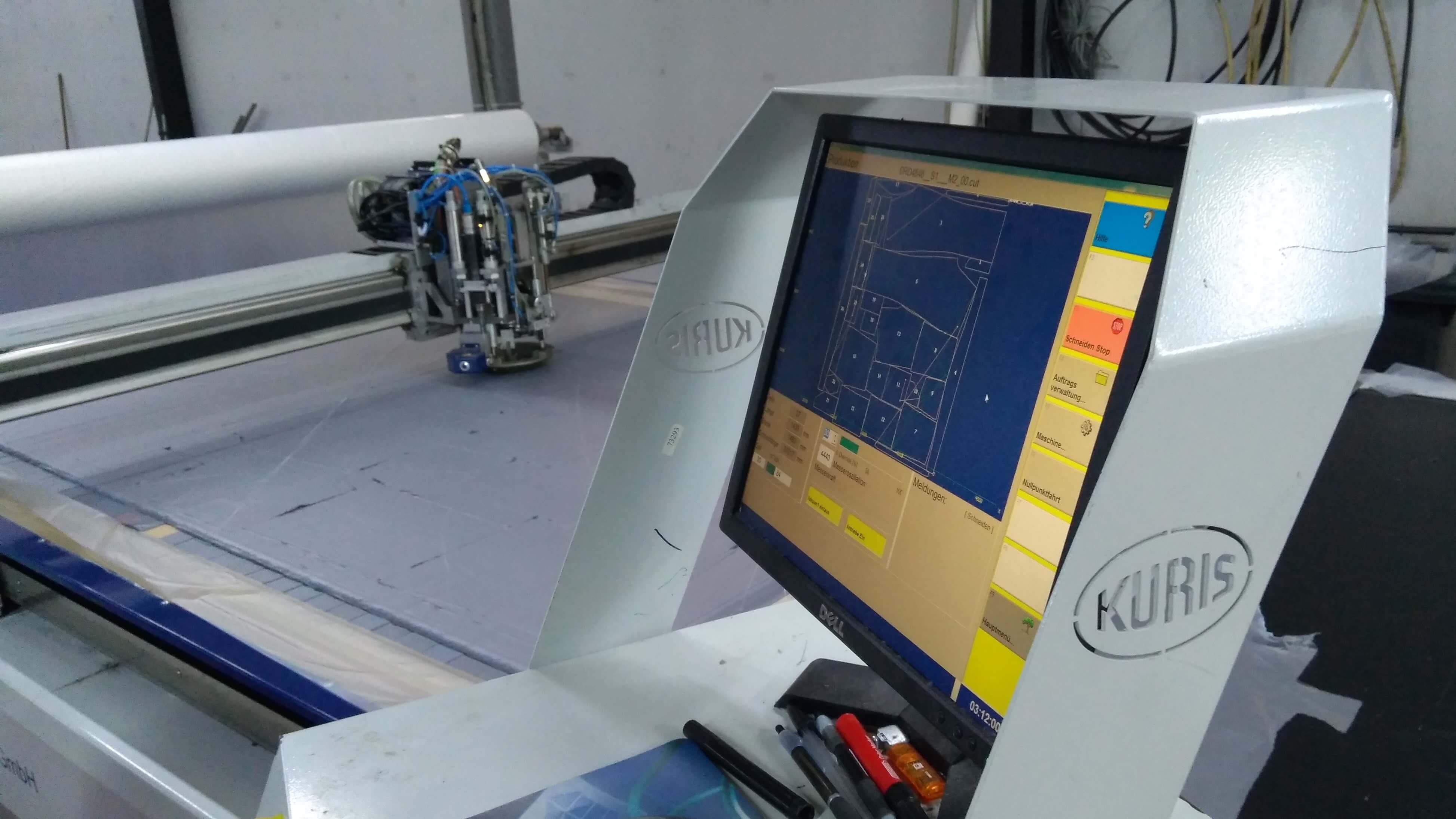

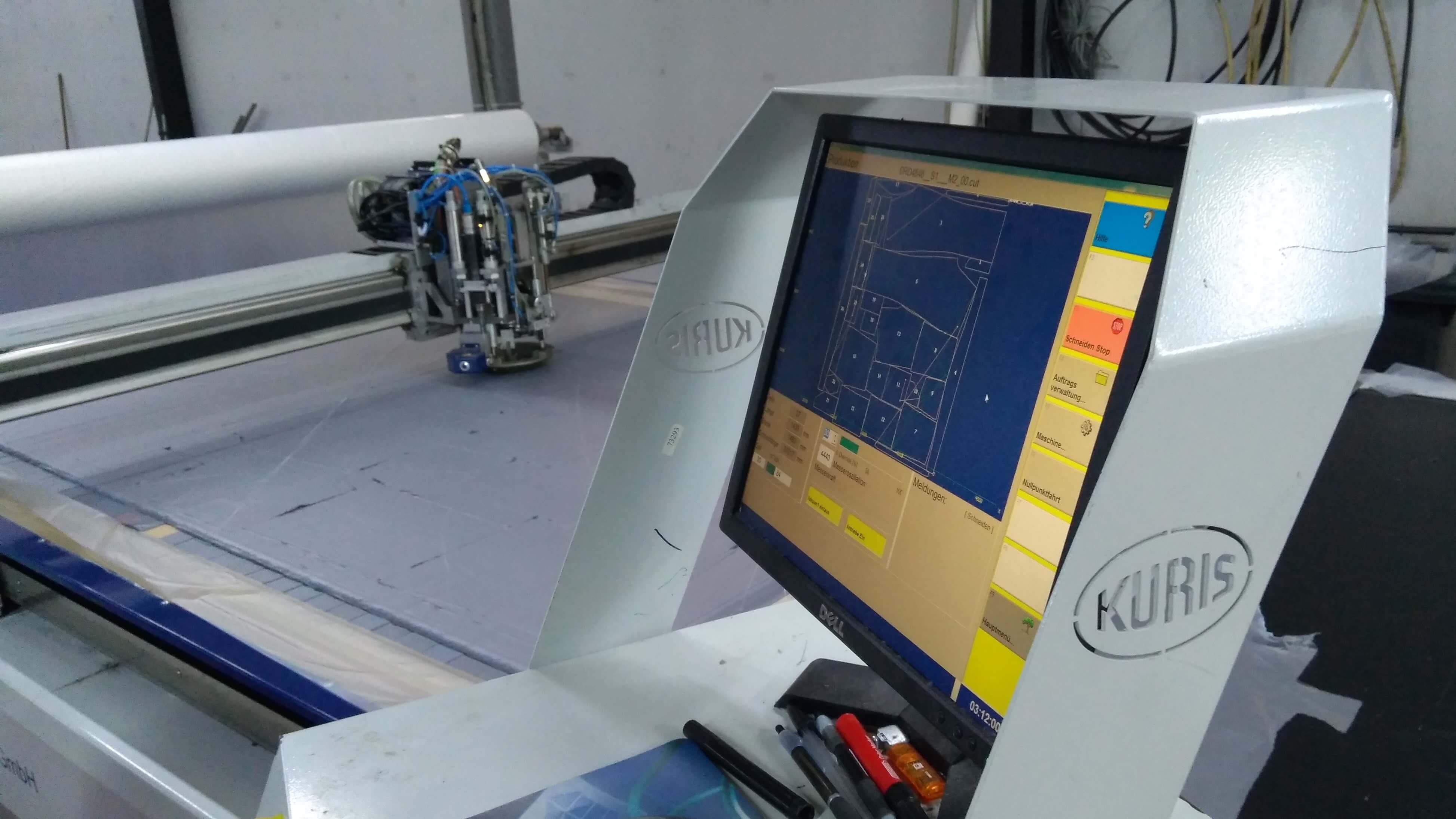

Cutting Room Planning

- Preparation and planning of cutting operations.

- Controlling jobs for automatic cutting machines.

- Calculate expected cutting time and capacity planning.

- Integrated with PDM/PLM, Pattern and Marker management and CAD programs for marker exchange and automatic nesting.

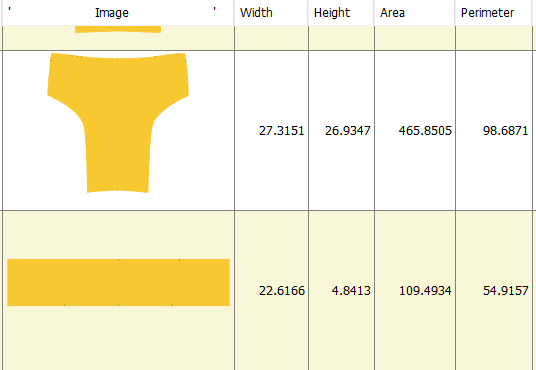

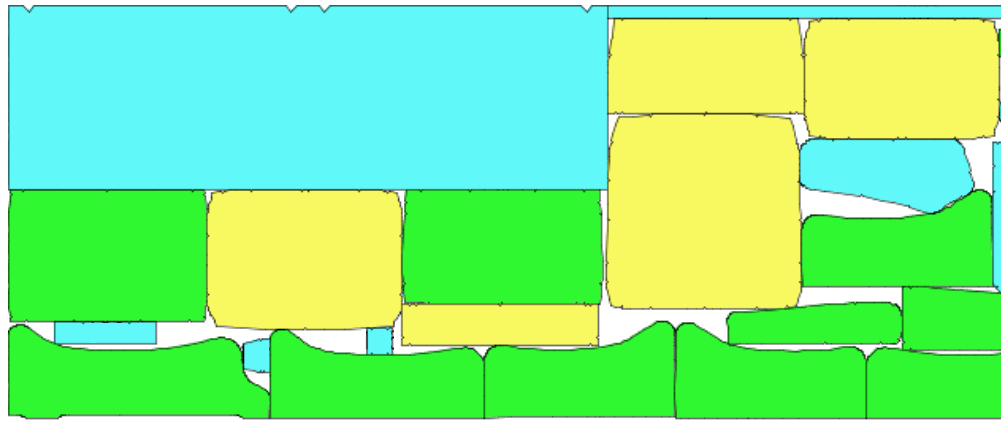

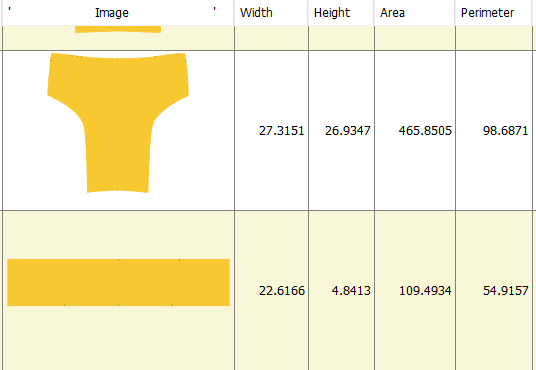

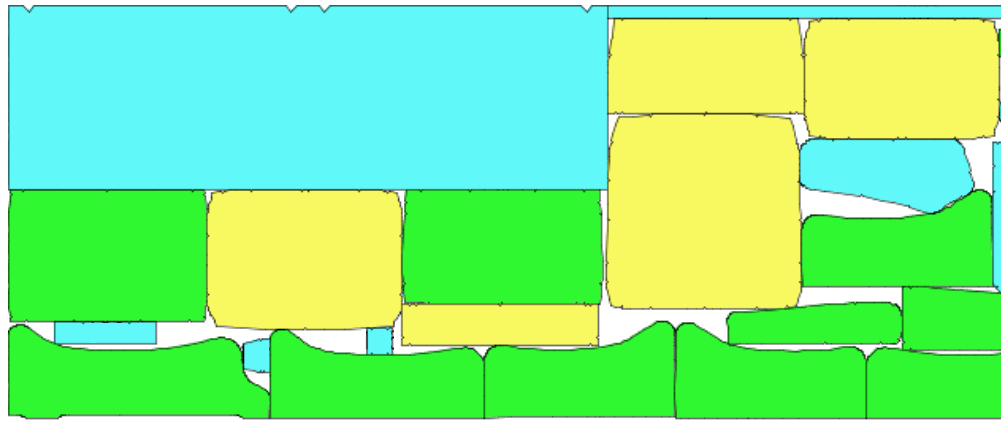

Cutting Visualisation

- Direct interface with cutting systems.

- Visualize cutting progress.

- Cut pieces, coloring by type or product.

- Speeding up cut pieces sorting and take-off.

- Single ply and multiple ply cutting support.

Sewing Room Planning and Production Follow up

- Operator and machine resource calculation.

- Production line balancing based on sewing plan and production order.

- Production follow up by scanning completed operations

- Scanning finished operations per piece or bundle.

- Monitoring production order progress and bottle necks.

- Registering defects and machine downtime.

- Possibilty of direct integration with sewing machines.

Quality control and spare pieces management

- Registering defective pieces after cutting or sewing processes.

- Possibility to measure dimensions based on pattern on screen.

- Stock management of spare pieces.

- Automatically creating cutting orders for compensation of defective pieces.

- Registering type of defects